E-MOBILITY

Emission Measurement

E-Mobility

Test Stands

- 48″ Chassis Dynamometer (Cars)

- 72″ Chassis Dynamometer (Commercial)

- Chassis Dyno (Motorcycle / ATV)

- EMC Chassis Dynamometer

- Environment Chassis Dynamometer

- Flat Road Dynamometer FRDM 20L

- Mileage Accumulation Chassis Dynamometer

- Multi-Motor Chassis Dynamometer

- NVH Chassis Dynamometer

- Pulsed Flat Road Dynamometer

- Powertrain Dynamometer (R2R)

- Tractor Chassis Dynamometer

- Wind Tunnel Balance

Automation

H2 Hydrogen Fuel Cell Testing

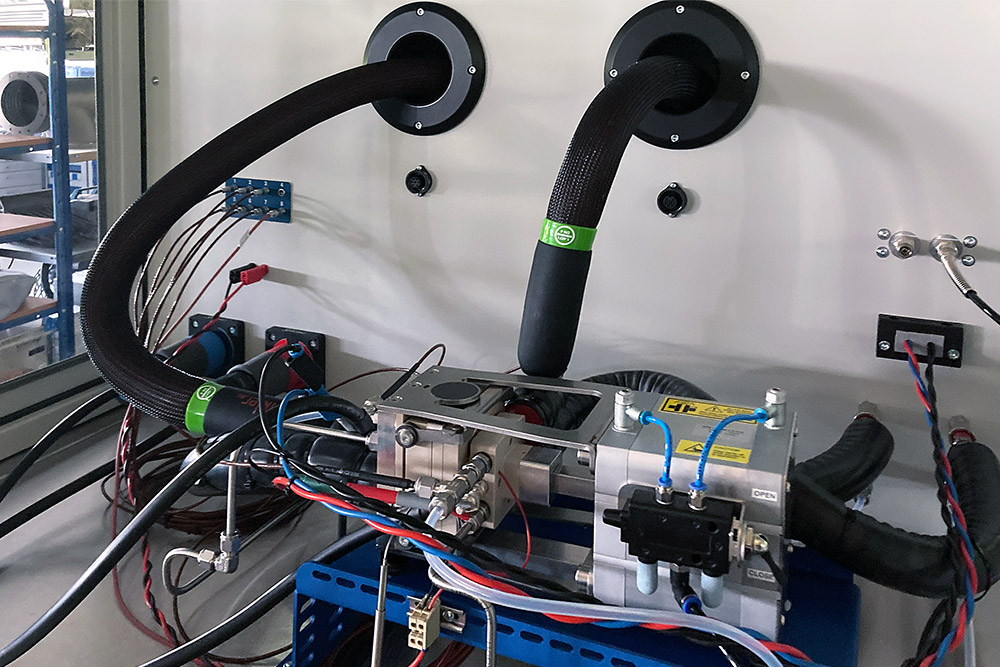

Hydrogen Fuel Cells: Testing of the Membrane Electrode Assembly with FC-MEA

With the H2FC-MEA, tests and characterizations are carried out on individual fuel cells or cell stacks under defined operating conditions. The H2FC-MEA is designed to be self-sufficient and flexible and based on a modular system. The test sequences parameterized with a sequence editor run directly on a real-time computer, which guarantees the uninterrupted execution and recording of very long test sequences.

Hydrogen fuel cells: Testing of the Membrane Electrode Assembly

Features

- Gas dosing with mass flow controller (H2 / air / oxygen)

- Dynamic humidification of the gases with bubble column reactors with a dry bypass to achieve high dynamics

- Adjustable operating points on the cathode and anode in terms of dew point, pressure, temperature and flow rate

- In the event of a fault, inerting with nitrogen at the cathode and anode

- Plausibility and monitoring functions (H2-warning unit, flow-monitoring, exhaust system, leak check, monitoring of customer-side media …)

- Automated, unmanned operation

- Measurement protocol and data export

- Possibility of connection to the customer‘s ATEX exhaust air system

Applications

- Anode and cathode preparation

- Automatic filling of the bubble column reactors for unmanned operation

- Cooling circuit for tempering the fuel cell (Delta p, Delta T or T regulation)

- Impedance spectroscopy to characterize the cells

- Electronic load (sink) for simulating

Technical Specifications

| Gas conditioning | ||

| MFC accuracy | ± 0.1 | % FS |

| ± 0.5 | % RD | |

| Humidification method | Bubble column reactor | |

| Dewpoint control accuracy | ± 1 | °C |

| Gas temperature range | until 130 | °C |

| Gas temperature control accuracy | ± 2 | °C |

| Temperature sensors | PT100 | |

| Pressure control range | 1,1-5 | bar |

| Pressure control accuracy | < 25 | mbar |

| Pressure sensor accuracy | ± 0.25 | % FS |

| Cooling unit | ||

| Temperature control accuracy | ± 1 | °C |

| Regulation modes | Δp, ΔT, T | |

| Pressure control range | 0-4 | bar |

| Temperature control range | -30 … 90 (with ext. Cryostat) | °C |

| Electric conduct. cooling medium | < 5 (optional: bypass ion exchanger) | μS / cm |

| Electronic load | ||

| Maximum input voltage | 12 | V |

| Minimum input voltage | 0 | V |

| Maximum current | 400 | A |

| Voltage measurement accuracy | ± 0.05 % RD | ± 0.02 % FS | |

| Current measurement accuracy | ± 0.2 % RD | ± 0.05 % FS | |

| Impedance spectroscopy | ||

| Frequency range | 10 μHz – 8 MHz | |

| Controlled voltage | ± 5 / ± 15 | V |

| Compliance voltage | ± 28 | V |

| Maximum current | ± 3 | A |