E-MOBILITY

Emission Measurement

E-Mobility

Test Stands

- 48″ Chassis Dynamometer (Cars)

- 72″ Chassis Dynamometer (Commercial)

- Chassis Dyno (Motorcycle / ATV)

- EMC Chassis Dynamometer

- Environment Chassis Dynamometer

- Flat Road Dynamometer FRDM 20L

- Mileage Accumulation Chassis Dynamometer

- Multi-Motor Chassis Dynamometer

- NVH Chassis Dynamometer

- Pulsed Flat Road Dynamometer

- Powertrain Dynamometer (R2R)

- Tractor Chassis Dynamometer

- Wind Tunnel Balance

Automation

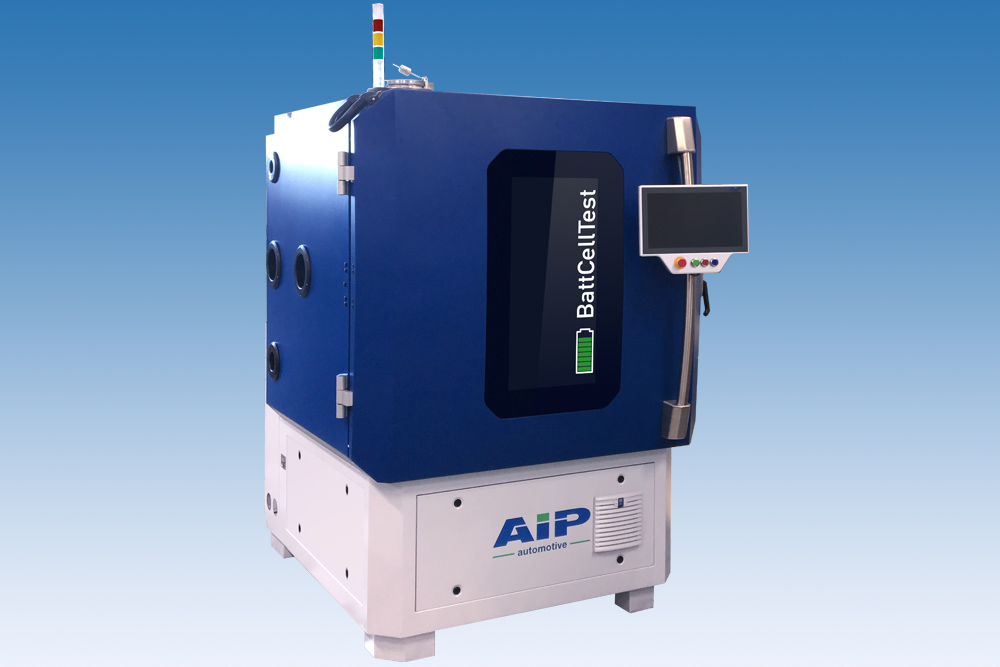

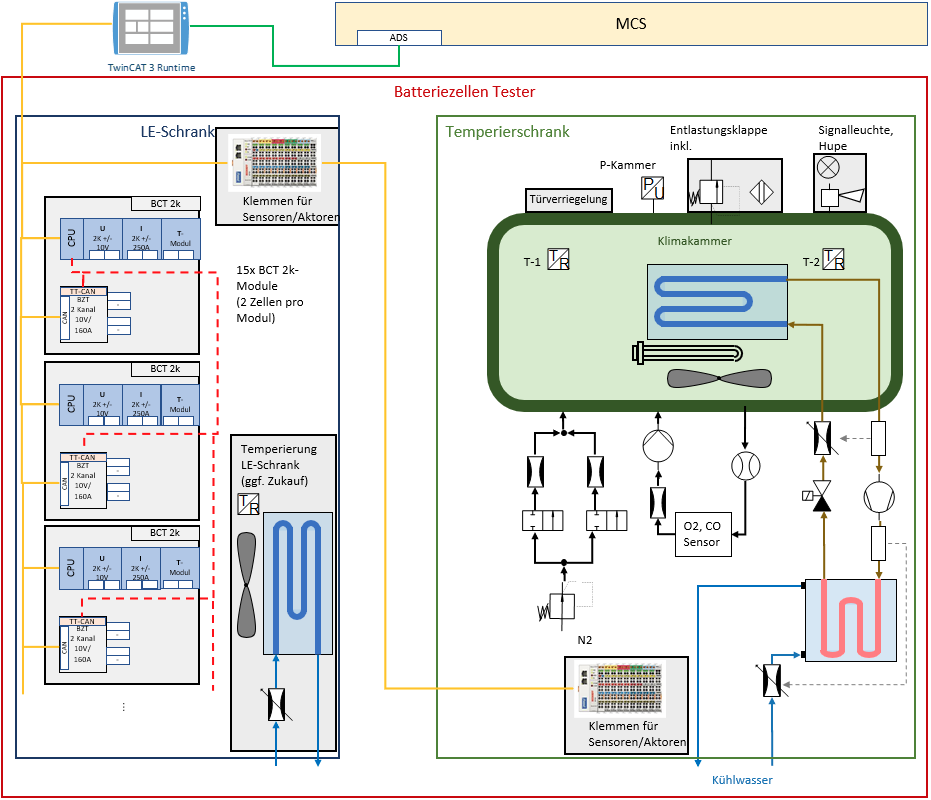

Battery Cell Tester

For precise and reproducible function tests for quality assurance (development of battery modules or battery packs)

The compact battery cell test system consists of a combined, dual cabinet system. There is a temperature test cabinet with a cooling / heating unit and an LE cabinet (power electronics). The LE cabinet is attached to the rear of the temperature test cabinet. An intermediate zone is used for thermal separation and for routing cables up to the through-hole plating in the temperature chamber. The system is suitable for battery cells up to 1,000 mm and a maximum weight of 80 kg / layer.

The temperature control cabinet is equipped with 5 layers, whereby the layers can be individually removed for external equipment. The contact with the power electronics takes place automatically at the end position of the layer.

Applications

- Exact testing of battery cells to ensure quality and performance

- Reproducible, realistic function, performance and aging tests

Advantages / Highlights

- Very compact design

→ power unit and temperature control cabinet from a single source - Suitable for battery cells with a length of up to 1,000 mm

- Testing multiple large cells per layer

→ max. weight 80 kg/layer - High-current tests per test item of 960 A duration and 1500 A peak

- Modular configurable channels

→ Adaptation to changing requirements is possible at any time

Technical Data

Temperature Control Cabinet

| Temperature range | -30 … +60 | °C |

| External dimensions W x H x D | on request | mm |

| Inside dimensions W x H x D | 1,200 x 1,000 x 600 | mm |

| Layer for test item | 5 (individually removable for external equipping) | layer |

| Loading per layer | 80 | kg |

| test piece size w x h x d | 1,125 x 160 x 560 (Standard layer for max. 6 test items) |

mm |

| Heating speed (IEC 60068-3-5) | 3 (empty cell) | K/min |

| 2 (200 kg DUT) | ||

| Cooling speed (IEC 60068-3-5) | 2 (empty cell) | K/min |

| 1 (200 kg DUT) | ||

| Heat compensation | 2 (at -30°C) | kW |

| 5 (at +20°C) | ||

| Ambient temperature | +10 … +35 | °C |

LE Cabinet

| Outside dimensions W x H x D | on request | mm |

| DC power channels | 30 | channels |

| Channels per layer | 6 (suitable for series and parallel operation) | channels |

| Current per channel | I nomen +plusmn; 160 | A |

| Overload ± 250 – S6 (60s) |

||

| Voltage | 0 … ± 10 | V |